Profiles & Accessories

Topco’s Cornices

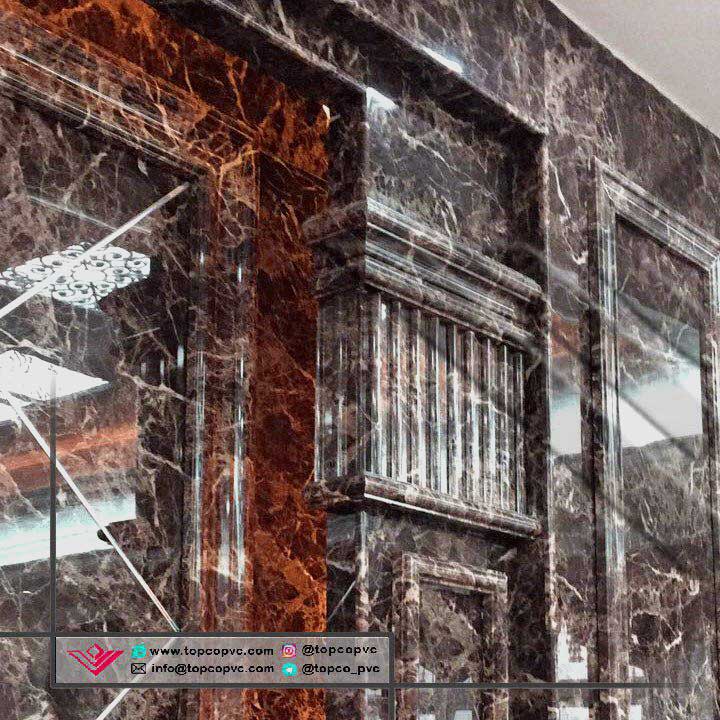

The cornice is used to decorate the corners of the ceiling, walls, partitions, columns, door frames, windows and elevators. Cornices are produced in different shapes and sizes and are selected based on the installation site and the type of interior design. The use of cornices in buildings has been popular and common since ancient times. In the past, they used types made of stone or bricks, but today, with the development of modern technologies, they use types of PVC, MDF and polystyrene instead of stone types.

Cornice or cornice mouldings have different uses such as protecting walls, framing walls, and creating dimensions on walls. In interior designs, the cornice is usually placed at two main points; The upper part of the wall close to the ceiling and the lower part of the wall at the point of contact with the floor. The types of cornices that are used for ceilings have an effective role in decoration of walls and columns. The cornice or belt that installed at the bottom of the wall is somewhat separating the floor from the walls. The more height of cornice makes interior design more beautiful.

Regardless of the aesthetics of appearance, since the cornice in general is prominent on the walls, its task is to protect the wall from damage caused by collision of furniture and to prevent the penetration of water from the floor to the walls. If the floor is laminated, the cornice will be used to cover the space between the laminate and the wall.

How to choose the appropriate cornice?

Aesthetic Appearance & Coordination

Water & Moisture Resistance

Washability

The wooden cornice is used in places where floors are covered by wood to create a calm and pleasant atmosphere.

MDF Cornices

Profiles & Accessories

One of the main studies to buy the cornice is how to choose the cornice for the desired location. The preservation of harmony of the interior design leads to a beautiful and pleasant place. If the floor is laminated, the cornice should be chosen by color that is two to three shades darker than laminate; Through this, it is possible to create a beautiful design on sides of the walls.

If the area of the house or workplace is small, or the ceiling is not high enough, it is better to use a 7 or 9 cm (3 to 3.5 inches) cornice, If the ceiling height is more than 3 meters (10 ft) or the area is more than 100 square meters (1100 ft2) the best option is a cornice with a height of 12 or 15 cm (5 to 6 inches).

Water & Moisture Resistance

The other factor that must be carefully considered is resistance of the cornice to moisture and water. Moisture and water can cause serious damage on walls. The best way to confront with moisture is using a cornice made form PVC. PVC cornice is completely resistant to water and moisture and is the best choice for crowded places such as restaurants, reception halls and corridors.

Perhaps the main reason for using the cornices in the architecture of buildings and public places is to prevent damage from possible collisions of objects with the wall. First of all, the cornice should have high quality so that it can prevent damage from impacts on the walls and in addition not be easily damaged.

Washability

Environmental health and population health are very important and must be considered when choosing a cornice. Wooden cornice is porous, so it absorbs water, when it does, the wood expands and warps causing structural problems. it is always one of the main concerns of the wooden cornice owners because it is exposed to danger when washing the floor. Wooden cornices are eventually rotted by washing and cleaning, and even cause insects to accumulate in decaying areas. PVC cornices are completely waterproof and washable by all kind of detergents.

The price of the cornice In the markets depending on the height, thickness, country of manufacture, and the materials used in its manufacture. In the markets, the wooden cornice has the highest prices, also the MDF cornice has high prices. It can be said that the price of the PVC cornice is commensurate with its quality. That is the reason of the high popularity of this type of cornice in the local markets.

The cornice in terms of manufactured material includes four general categories of stone, wood, MDF and PVC. MDF and PVC cornice are the most widely used because they have such features as aesthetic appearance, ease of installation, and reasonable price.

Stone Cornices

The stone cornice is usually used in places where the floor is covered by stone, and in this case to protect the harmony of the interior design, the selected cornice must be of the same material and color of the stone which used in the floor.

The wooden cornice is used in places where floors are covered by wood to create a calm and pleasant atmosphere.

MDF Cornices

MDF cornice is the most common type. Today, MDF cornices are available in markets with scratch-resistant PVC veneer Due to the weakness of this type of cornice.

This type of cornice can be used in all places with stone and ceramic floors, and in places with wooden and parquet floors. PVC cornice has many advantages over stone and wood, including water and moisture resistance, ease of installation, etc. The PVC cornice is produced in two shapes, solid and hollow. The high resistance to moisture of this type of cornice made PVC an effective tool against moisture. The high resistance to moisture of this type of cornice made PVC an effective tool against moisture and humidity.

It can be concluded that today the PVC cornice and the artificial PVC veneered MDF cornice due to various textures and colors and also reasonable prices have replaced by traditional types of stone and ceramic cornices.

Profiles & Accessories

Topco Industrial Group manufacturer of Topsheet (PVC wallcoverings) in various and modern textures, in order to meet the requirements of customers, has produced various types of profiles and accessories (corner, frame, edge, etc.) made from PVC and aluminum in different dimensions and textures (stone, wood and wallpaper). Topco PVC profiles, in addition to its aesthetic appearance, have excellent color durability for many years to come.

All Topco Industrial Group’s product are washable, anti-bacterial, eco-friendly and recyclable. Topco PVC profiles unlike MDF profiles are free of methanol or unstable organic compounds and are resistant to environmental factors such as moisture and fungi. This product is light and corrosion and impact resistant.

The high flexibility of Topco products makes the installation of PVC profiles easy and simple at corners and curvatures.

Topco Industrial Group has produced various types of PVC profiles and aluminum accessories in order to ease of installation and to achieve more aesthetics. To see PVC profiles and aluminum accessories, click on image below.

For More Information, Call Sales Expert

00989128902984